The manufacturability of a device depends on your individual design and the interaction you need between the various design elements. In this respect, the following design guidelines for polymer-based microfluidic devices give you a better understanding of possible limitations in the design of a specific structure. For the microfluidic design, you have to consider two aspects besides the functionality right at the start of the design process: first of all, you have to check whether the design can be realized by replicative technologies – which allows you low-cost mass-manufacturing – like injection molding, and secondly whether the back-end processes, in particular the assembly (usually the secure sealing of the fluid with a cover lid), can be ensured. Besides the purely technical constraints, cost considerations can also have an influence on the manufacturing route you will choose, as different methods for mold insert fabrication have not only different technical constraints (minimum feature size, maximum height, surface roughness, etc.) but also different cost ranges.

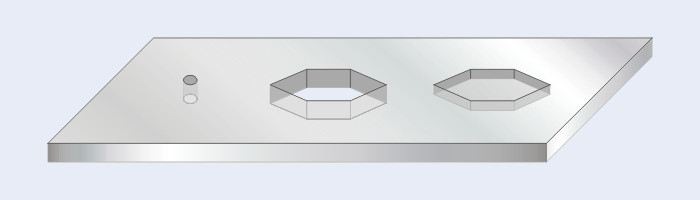

Through-Holes, Open, and Structured Areas

Feature Density

In order to allow for a good bond between a structured part and a cover foil, two adjacent channels or similar features should be separated by at least twice their width, but not less than 200 μm. Not more than 50% of the overall surface area should be covered with structural elements.

Distance to device Edges

In order to allow for a good bond, features should have a minimum distance from the edge of the device of 2 mm. The larger the device and the feature size, the larger this distance should be.

Minimum Feature Depth

Structures should have a minimum depth of 5 μm for features < 100 μm. For features between 100 and 1000 μm, the minimum depth is 15 μm.

Minimum Residual Thickness of the Device

The minimum residual thickness of the device in structured areas is 500 μm for areas > 1 cm2. For smaller areas, a lower residual thickness might be possible, depending on the overall device layout.

Maximum Feature Width

There is no practical limit to the feature width, however in the case of features wider than 4 mm, support structures to prevent the cover lid from sagging might have to be included in the design.

Aspect Ratio

For injection molded parts, the aspect ratio for microstructured elements should be less than 2.

Through-Holes

The minimum diameter of through-holes realized by standard core pins is 500 μm. Smaller holes can be realized with additional means upon request.

Open Areas

Open areas are possible.

![]()

General Design Guidelines for Mechanically Machined Mold Inserts

For the mold inserts we fabricate by using precision machining (for example in brass or stainless steel), you have to take the following design restraints – in addition to the ones mentionned above – into consideration:

Minimum Feature Size

The minimum feature size for sunk features (i.e. features where the mold insert material has to be removed) is 50 μm. For features in the range between 50 and 100 μm, the aspect ratio is limited to 1.5.

Minimum Radius of Curvature

At intersecting features (e.g. channel crossings), a radius of curvature of 40 μm occurs as standard. Smaller radii down to 10 μm are available upon request and depend on the aspect ratio of the respective structure.

Feature Heights

Different height steps as well as slopes of up to 45°–90° (depending on absolute feature size) are possible.

Surface Roughness

Mechanical machining results in a surface roughness of the order of 0.5–1 μm RMS. The features can be polished if protruding (e.g. channel floors in the polymer part which are ridges in the mold insert), to create an optical finish (roughness < 50 nm RMS).

![]()

General Design Guidelines for Mold Inserts Fabricated Using Lithography and Electroplating

For the mold inserts we fabricate by using lithography and electroplating (either e.g. from a silicone or glass master), you have to take the following design restraints – in addition to the ones mentionned above – into consideration:

Minimum Feature Size

The minimum feature size is 10 μm. For features in the range between 10 and 100 μm, the aspect ratio is limited to 1.5.

Maximum Height

For lithography-based mold inserts, the maximum feature height is 100 μm.