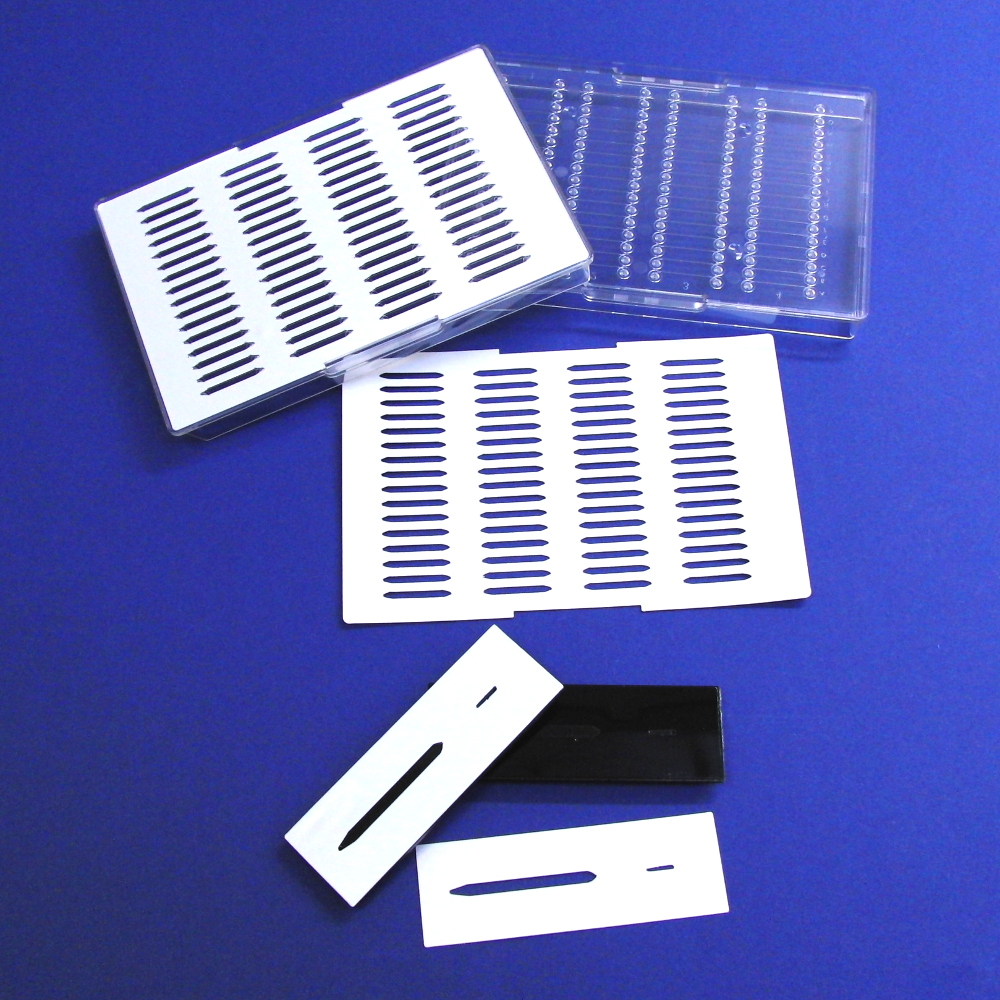

Our customers frequently request the integration of protein- or DNA-arrays in a chip. Although we offer a spotting service, many of our customers in research labs want to evaluate special targets and functionalization methods and do their own spotting. If you are one of those customers, we can provide you with several chip types, that have an integrated fluidic channel open for the spotting at your facility. The chips come with a fixed double-sided adhesive tape of approximately 140 μm thickness. That means, after the spotting you just remove the protective foil and you can mount either a thin foil of the same material or a glass slide on top.

Customize Standard Chips

Microfluidic ChipShop offers you several straight channel chips for self-assembly of the cover lid on spotted devices. In order to start right away with your own spotting tasks, we recommend the spotter instrumentTWO-300P by M2-Automation, which provides an easy to use and robust micro-dispensing (spotting) solution.

microfluidic ChipShop recommends the following chips for your customization:

- 1-Channel Chip – Fluidic 95

- 1-Channel Chip – Fluidic 268

- 2-Channel Chip with Waste Chamber – Fluidic 272

- 4-Channel Chip – Fluidic 138

Basically we deliver any of our standard chips without a bonded cover lid, for you to connect the chip with a specific bottom that reflects your requirements (e.g. glass slide). As – somewhat generic – design rules, you should take the following aspects under consideration:

- Minimum channel width that can be cut into the double-sided adhesive tape: 200 μm

- Minimum radius of curvature of the structures cut in one line in the tape: 500 μm

- Minimum distance between two adjacent cut-out structures: 1 mm

- In general, the remaining tape film should have as much mechanical stability as possible, so that you can properly mount it onto the molded substrate. That means, the shorter the cut-out sections and the more widely spaced, the better.