On chip valving gives the possibility to direct and dose fluids freely according to the respective needs. Simple membrane valves embedded in the fluidic design allow for an on-off functionality whereas rotary valves enable to channel fluids in different pathways or to dose liquids in loops on a chip or directly in the valve itself.

Rotary valve chip

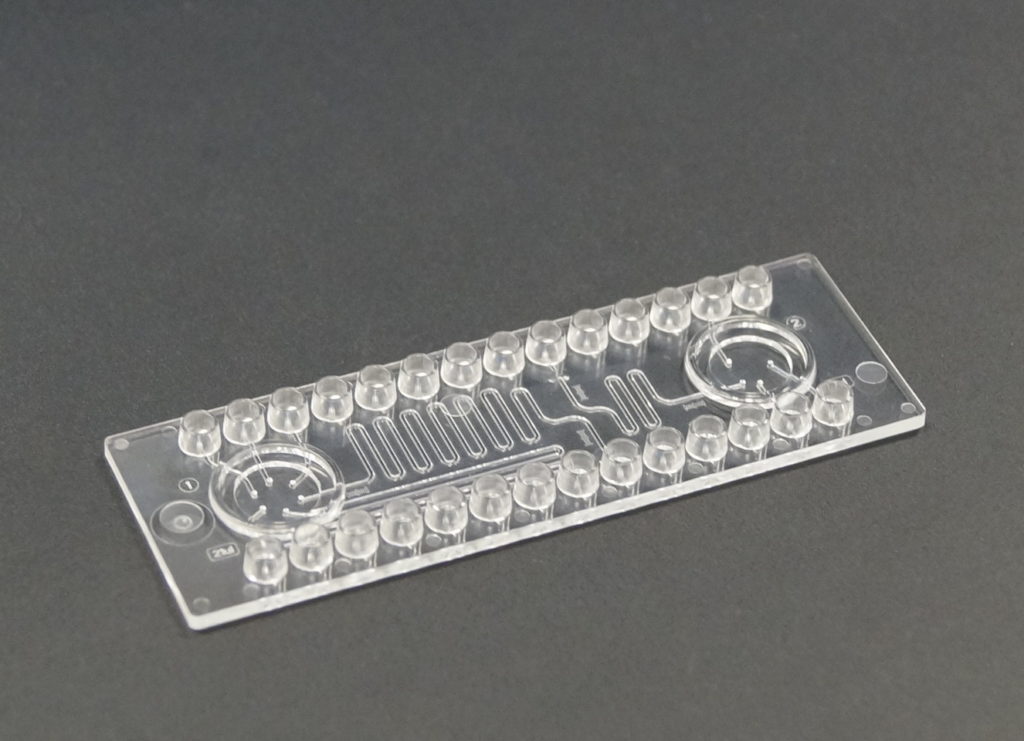

Turning valves allow the targeted distribution of liquids and gases in channel networks, to actively open and close channels and to meter liquids. In instruments the valves are operated in an automated manner through turning the valve body in previously defined increments. For evaluation of metering on chip and in the valve body we offer a turning valve test chip. Turning valves can be operated either manually with a valve actuator, as shown below, or automatically with microfluidic ChipShop’s ChipGenie® edition TV.

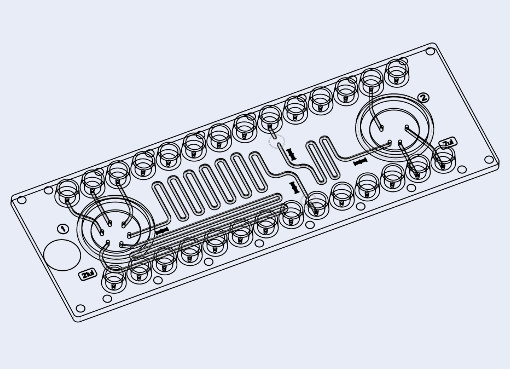

Schematic Drawing of Fluidic 155

Fluidic 155

Membrane valve chip

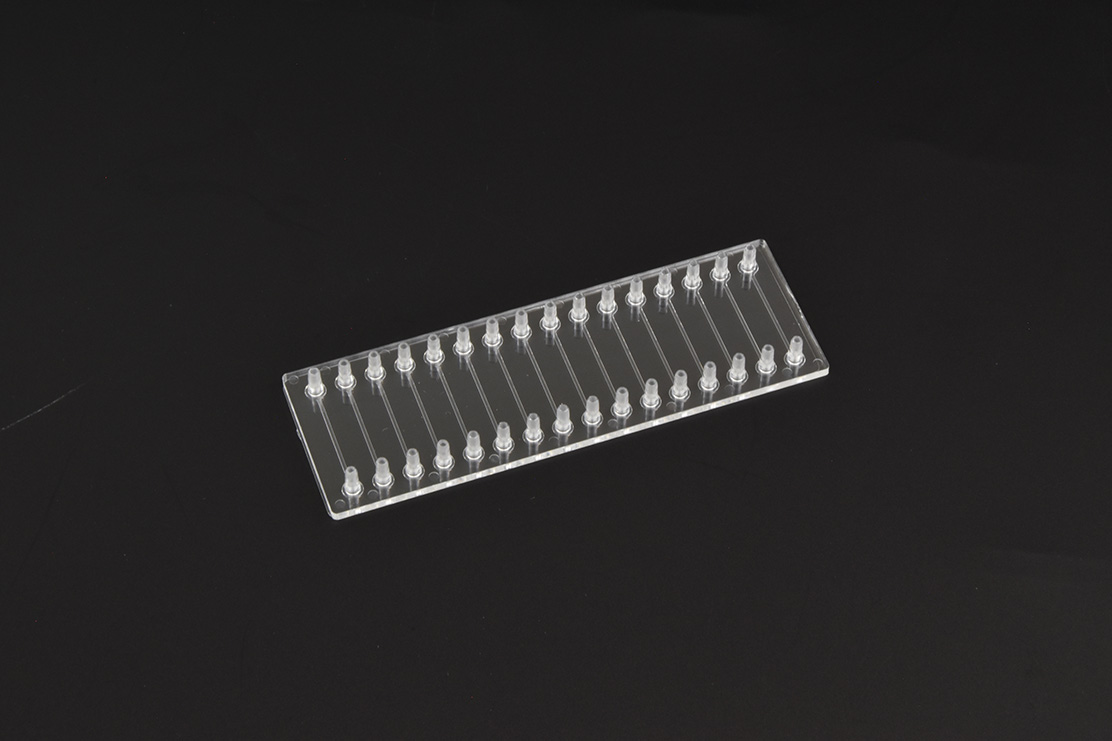

The membrane valve chip Fluidic 1367 has 16 identical channels per chip and comes with olive interfaces. This enables direct contact, via tubing, to a pump system.

Each channel has an integrated membrane valve structure at the inlet, right below the olive interface, that can be controlled separately via a valve actuator. The membrane vlave is normally open and allows fluid to pass. Applying force from below, with a mechanical actuator, will lead to closure of the valve and hence stop the flow. The chip can be powered with liquids or gases and the valves remain tight up to a maximum inlet pressure of 3 bar.

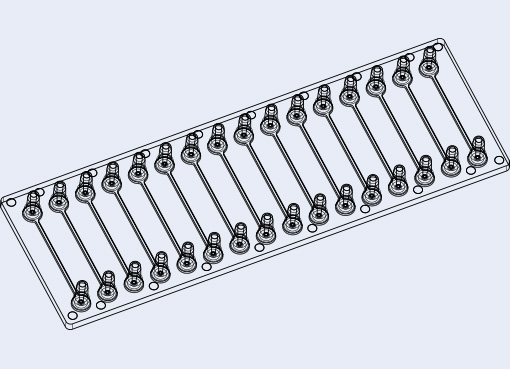

Schematic Drawing of Fluidic 1367

Fluidic 1367