microfluidic ChipShop – The company

Our mission at microfluidic ChipShop is to shrink the biological and chemical laboratory and to bring lab-on-a-chip systems into daily laboratory life.

The lab on the chip – miniaturized solutions as easier and faster analytical tools for the life sciences, diagnostics, analytical sciences, and chemistry – are at the core of microfluidic ChipShop’s business. The company, founded in 2002 as a spin-off of the Fraunhofer Institute for Applied Optics and Precision Engineering and the Application Center for Microtechnology Jena, has become a world leader in this rapidly growing technology sector. Specialists from microfluidics, precision engineering, polymer microtechnology, medical technology, chemistry, biology, and diagnostics form a multi-disciplinary team to develop and manufacture “lab-on-a-chip” systems primarily in polymers. Using industrial manufacturing techniques allows for a seamless transition from development stage via small batch production up to mass fabrication, which plays an important role in our comprehensive customer support.

The Smallest Details – Precision Manufacturing on the Micrometer Scale

A unique feature in microfluidic ChipShop‘s services is offering miniaturized components and systems both as self-developed standard products as well as customized solutions from prototype to volume production. ...

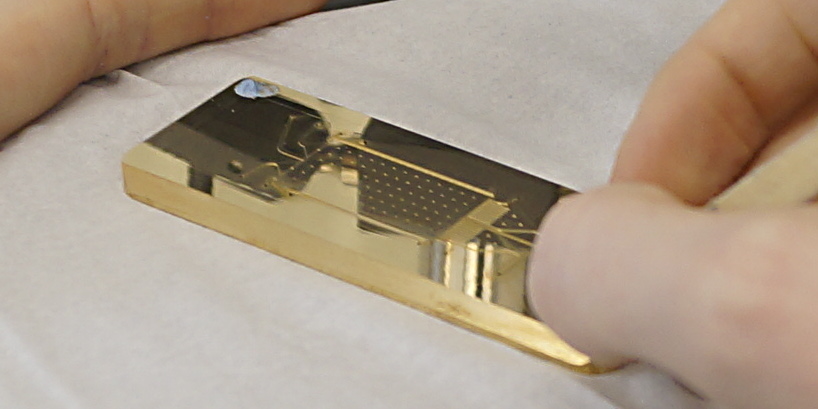

microfluidic ChipShop covers the entire value and technology chain, starting from the design of the microstructures, followed by mold-insert fabrication, polymer replication using precision injection molding, hot embossing, or casting, mechanical processing steps up to the biochemical functionalization of surfaces and reagent storage on the chip, and finally, industrial quality control. In addition, microfluidic ChipShop supports customers in the miniaturization of their biological and diagnostic tasks, e.g. in the transfer of biological assays on the chip, the development of PCR protocols for chip-based applications, or the selection of suitable materials for the immobilization of biomolecules. For these means, the company has its own application department. Furthermore, the development of complete systems including instrument, chip, and associated application protocols is carried out by microfluidic ChipShop; examples include systems for the polymerase chain reaction in a continuous flow or chip-based capillary electrophoresis. To implement these highly complex projects, microfluidic ChipShop maintains a worldwide network of research and development collaborations. In order to fulfill our customers’ needs and to deal with all regulatory issues associated with the development and fabrication of diagnostic and medical devices, microfluidic ChipShop has been certified according to DIN EN ISO 9001 and DIN ISO 13485 since 2003.

Standardization: Established Formats – Innovation at the Core

Lab-on-a-chip technology as a novel technology offers a wide range of advantages for different applications and at the same time raises some challenges. On the one hand, use restrictions for novel tools need to be conquered, while on the other hand the introduction of new technologies needs to be affordable. ...

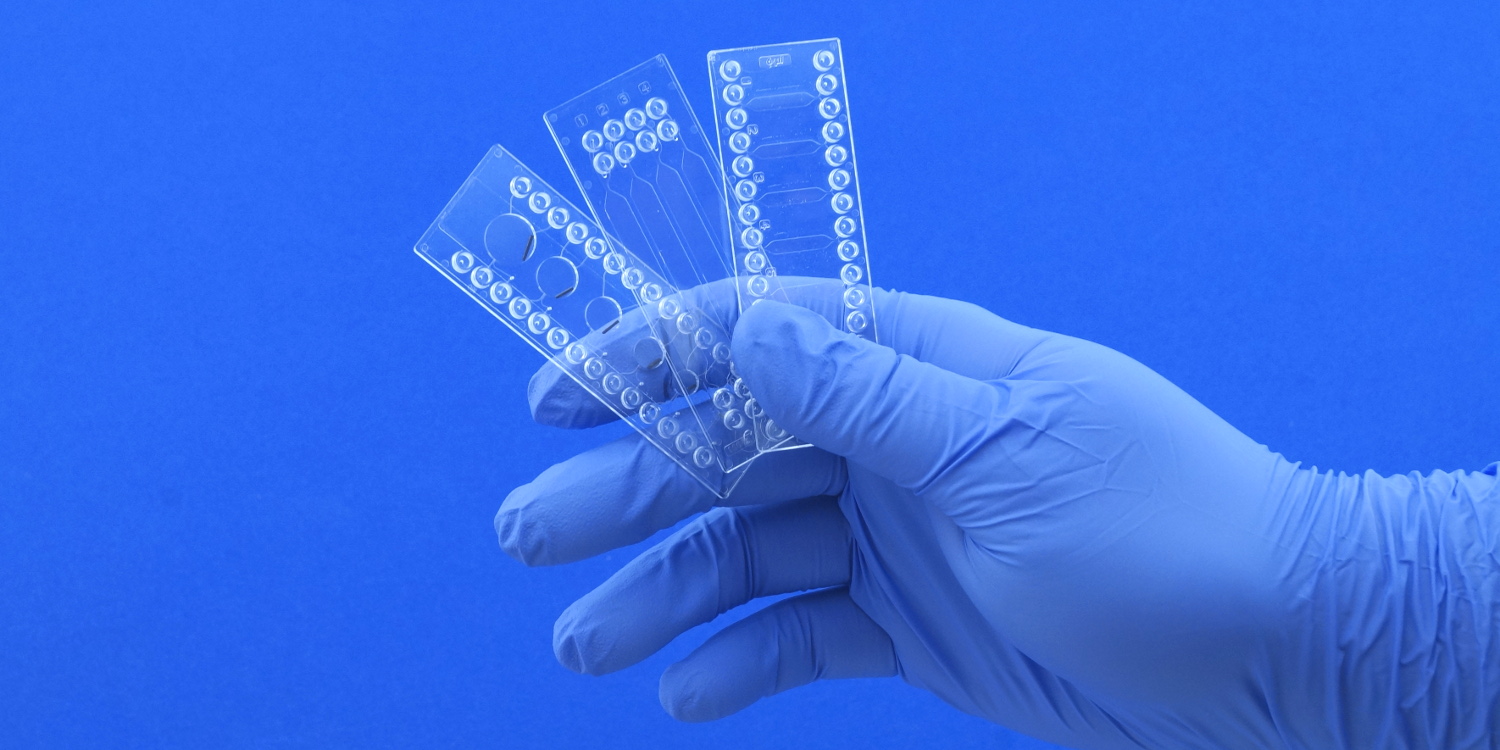

In order to meet these challenges, microfluidic ChipShop pushes standardization efforts vigorously: In chip formats, microfluidic ChipShop uses existing laboratory standards, like the microscopy slide or the microtiter plate, allowing for the use of standard laboratory equipment, like microscopes, pipettes, or laboratory automation. Directly integrated fluidic interfaces enable an easy chip-to-world connection and a seamless transfer of liquids from the standard lab to the micro world. Another advantage of the strict implementation of this standardization concept is cost efficiency. During the development process, an investment in an injection-molding tool is a significant hurdle, especially for small- and medium-scale production volumes. To overcome this obstacle, microfluidic ChipShop has various injection-molding tools that can be used on existing platforms – ranging from microscopy slides, via microtiter plates, to the CD format – for the integration of custom-specific designs. This approach not only minimizes costs, but also enhances the development process, since the time from design release to the first chips in our customers’ hands is reduced significantly.

Miniaturized Solutions for Diagnostics, Analytical Sciences, and Life Sciences

Miniaturization has already transformed the world of electronics and became a driver for many markets. Now it’s a driving force for an innovation in the life sciences, diagnostics, analytical sciences, and chemistry, which is labeled “lab-on-a-chip.” ...

The use of micro- and nano-technologies allows for the development of fast, portable, and easy-to-use systems with a high level of functional integration for applications such as point-of-care diagnostics, forensics, the analysis of biomolecules, environmental or food analysis, and drug development. The core of such “lab-on-a-chip” systems are polymer substrates in standard laboratory formats, such as microscopy slides or microtiter plates, equipped with miniscule structures for the transport and handling of samples. All the functionalities of a chemical or biochemical laboratory, such as the mixing of liquids, aliquoting, the amplification of biomolecules, the synthesis of novel materials, the hybridization of DNA molecules, or the detection of specific substances by optical or electrochemical methods, can be integrated in a single chip. Furthermore, components, such as filtration or separation membranes, valves, biochemical sensors, electrodes, and magnetic beads, can be integrated into a micro-structured polymer substrate. The integration of biochemical functions in a single chip makes numerous time-consuming and potentially error-prone individual steps redundant, such as multiple pipetting or sample transfer from one device to another.